Aqua (Shrimp/Sinking Fish/Floating Fish) Feed Plant

"Feed stable enough to exist in water"

The basic principle and process flow of the aqua feed plant is almost same as of the animal feed plant. Some additional machines are part of the process line to achieve ultra-fine grinding, dust free oil coated feed as finished product.

Batch premixing

Premixing of raw material of different bulk densities results in uniformly mixed ingredients for efficient grinding. It also results in steady load on hammer mill for optimum throughput with desired particle size.

Local aspiration units for conveyors The conveying of fine powder in bucket elevators and conveyors makes feed plant dusty. To make it dust free, local aspiration units with integral blower are directly mounted on conveyor body. The units are very effective and the recovered powder material falls back into the conveyor itself hence no more arrangements are required for collection and conveying separately.

Ultra fine grinding

Two stages of grinding for achieving the desired results. First stage of grinding through high speed Hammer Mill which converts raw material into fine powder. In second stage, pulverisers achieve ultra- fine powder suitable for pelleting/extrusion. The ultra-fine particle size is one of the prerequisite for pelleting/extrusion through fine hole die (may be 0.8 mm).

Pneumatic conveying

The ultra fine powder, from the out let of pulveriser gets transferred through pneumatic conveying arrangement for next operation. The pneumatic conveying system consisting of cyclone, jesma filter, airlock & blower makes the fine grinding system more efficient without loss of fine dust.

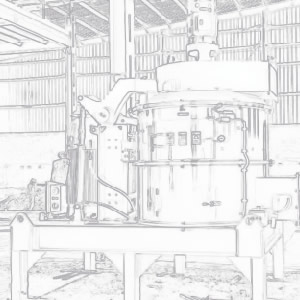

Conditioning

Multistage conditioning for complete sterilization to get hygienic & safe feed. Provides optimum preparation of mash with right combination of heat, moisture and retention time (upto 180 sec) before pelleting.

Post conditioning

Application of post conditioner before final cooling for further enhancement of water stability in sinking feed.

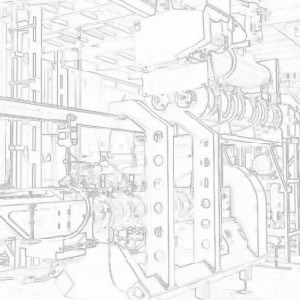

Extrusion

The ultra fine mixed mash feed from the live bin above extruder gets dosed through dosing feeder to conditioner(s) and enters into the extruder for final extrusion. The puffed extruded feed gets cut into the desired length with the help of variable speed rotating cutting knife.

Dryer

The hot extruded feed from the extruder gets transfer to multi pass dryer for reduction in moisture to desired level.

Oil coating

The hot pellet feed from the dryer gets transferred through rota shaker before entering into oil coater. The fine mist of oil from air-o-matic nozzles gets deposit on pellet feed and spreads uniformly on the pellet surface and makes the feed stable in water.

Cooling

The oil coated hot pellet feed then gets transferred to the counter flow cooler. It is cooled to the ambient temperature for storage into the bagging bins.

Recycling of over size particles

Use of plan shifters at different stages to segregate the oversize/fiber particles for recycling/removing. The desired powder is taken upstream for further processing.

Dust free feed before final bagging

The provision of gyro sieve before bagging station separates the powder that gets generated while conveying through elevators/conveyors and supply the ZERO DUST feed for bag packing.

Aqua feed in 25-40kgs. bags are auto weighed and stitched for despatches.